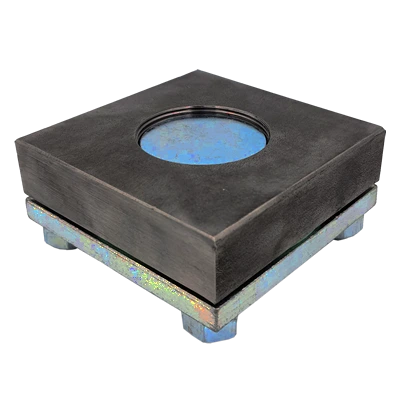

Description

The Oil Drain Mechanism DIN 42548 R is a critical accessory used in oil-immersed power transformers to ensure the complete discharge of residual oil trapped beneath the main drain valve. Over time, sludge, water, and other contaminants accumulate in the lower sections of transformer tanks. Without a proper drainage mechanism, this residue cannot be fully removed, affecting the performance and longevity of the transformer.

Manufactured in compliance with the DIN 42548 R standard, Hann Metal’s oil drain mechanism provides an effective solution for clean and full oil evacuation. It is designed to operate under high temperatures and withstands transformer oil up to 120 °C without leakage. The product has passed all leak and pressure tests, ensuring reliable operation even in critical transformer systems.

Why Is It Necessary?

Standard drain valves often leave a portion of oil at the bottom of the tank. This can reduce the effectiveness of oil replacement or maintenance operations. Using a dedicated oil drain mechanism ensures total evacuation, preventing oil degradation, improving insulation levels, and minimizing the risk of internal corrosion or failure.

Construction and Material Options

Our oil drain mechanism can be manufactured using carbon steel, AISI 316L stainless steel, or duplex stainless steel (1.4462), depending on your application and environmental conditions. It features a durable and maintenance-free structure, compatible with various transformer designs.

Technical Specifications:

-

Standard: DIN 42548 R

-

Function: Residual oil discharge from under the drain valve

-

Temperature Resistance: Up to 120 °C

-

Sealing: Leak-tested and pressure-certified

-

Material Options: Carbon steel / AISI 316L / Duplex stainless steel

-

Application Area: Power transformer tanks, industrial energy systems

Advantages:

-

Enables full drainage of old and contaminated oil

-

Leak-proof and durable construction

-

No maintenance required

-

Easy to install, compatible with standard tank designs

-

Suitable for extreme environments and operating conditions

Who Should Use This Product?

-

Transformer manufacturers

-

Transformer maintenance service providers

-

EPC contractors in power projects

-

Industrial energy facility operators

-

Power transmission and distribution companies

With Hann Metal’s DIN 42548 R-compliant solution, you can maintain clean and efficient transformer operation, extend the lifespan of your equipment, and reduce operational risks. For technical drawings, quotations, or product support, please don’t hesitate to contact our team.